HULL DEVELOPMENT

We offer a wide range of our own designs, developed with focus on motions and constructability. Through our projects we have proven that we are able to deliver innovative, high-quality and cost-effective solutions for the maritime industry.

HULL DEVELOPMENT

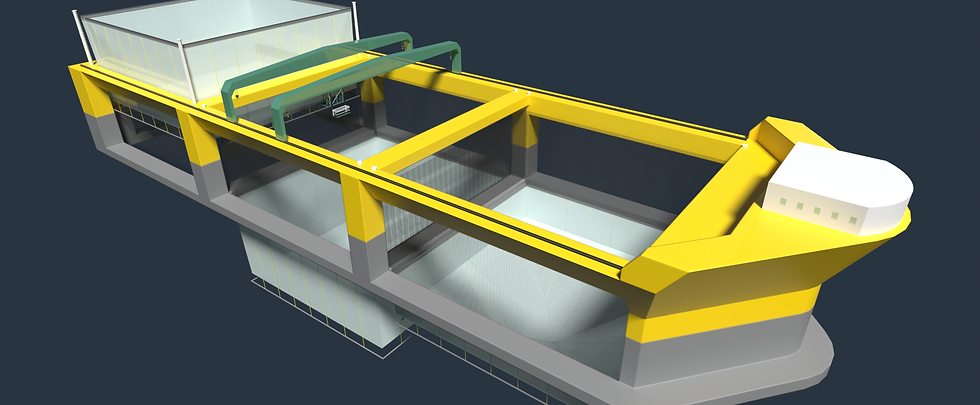

Cargo Transfer Vessel – CTV (Patent granted)

CHALLENGE

How to get oil directly to the market without reloading the cargo, either at terminals or by ship-to-ship transfer.

GOAL

Develop an offshore loading solution with focus on cost saving, safety and flexibility for customers, without any modification to existing infrastructure.

SOLUTION

Cargo Transfer Vessel (CTV) = New flexible concept connecting offshore fields to the market by direct loading to trading tankers. Patented by Cefront Technology with safety, cost and operational advantages over current solutions such as CALM buoys and shuttle tankers.

HULL DEVELOPMENT

Cefront spread-moored hull design (Patent granted)

Design developed to use the best of both worlds (Ship-shaped and cylindrical). Developed design fulfilling the targeted criteria of:

-

Favourable motions

-

No turret required in harsh environments

-

Simple design - hull structure similar to conventional ship

-

Low risk/cost

Today design has been developed for:

-

CO2-storage

-

FSO/FPSO/FLNG

-

Freshwater generation and storage

-

Flexible risers in Brazilian waters

-

Flexible risers in North Sea environment

-

Steel catenary risers in Brazilian waters

-

Hull sizes from 1,000,000 – 2,000,000 bbls evaluated with possibility to scale up or down

-

Wave environment up to Hs = 16m considered

HULL DEVELOPMENT

Fishfarm in exposed areas

Developed for operation in exposed areas

-

Turret moored – may be disconnected for service and maintenance

-

Closed sides to reduce exposure to salmon louse

-

Large capacity for storage of fish food

-

Efficient feeding and fish handling arrangements

Cefront has conducted:

-

Hydrodynamic analysis

-

Structural analysis

-

Equipment layout